DETAILS

Product Overview

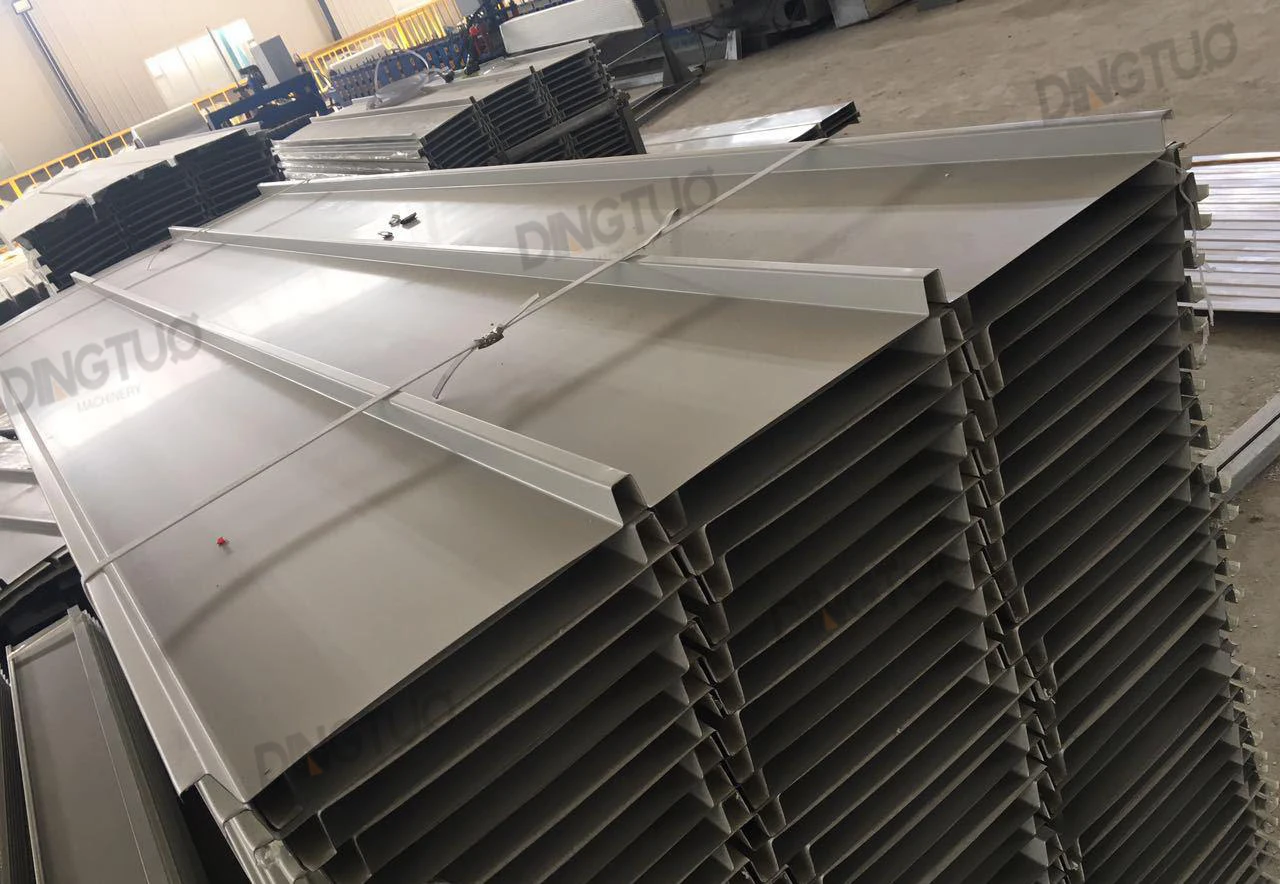

Packing box ceiling board

Package container house ceiling panel equipment is used to produce and install ceiling panels for package container house roofs. Here is a detailed introduction to this device:

1. Equipment type

Automated production line: including multiple automated equipment, which can efficiently complete the manufacturing and processing of ceiling panels.

Semi-automated equipment: Some processes require manual operation, but it can still significantly improve production efficiency.

Stand-alone equipment: independent equipment used for specific process operations, such as cutting, pressing, etc.

2. Main components

Feeding system: used for automatic feeding of raw materials to ensure continuous production.

Forming machine: Process raw materials into ceiling panels of specified shapes and sizes. The forming machine may be a roll forming machine or a profile press.

Cutting system: Cut the formed ceiling panels according to preset dimensions. CNC cutting systems are usually used to ensure accuracy.

Conveyor belt: used to transport ceiling panels and semi-finished products, connect various process equipment, and ensure the continuity of the production line.

Coating equipment: Surface treatment of ceiling panels, such as coating or spray painting, to improve their durability and aesthetics.

Heating and cooling system: Heating or cooling the material during the molding process to ensure the plasticity of the material and the stability of the finished product.

Control system: A central control unit, usually equipped with a PLC (Programmable Logic Controller), used to control and monitor the operation of various parts of the production line.

3. Main features

Efficient production: Automated equipment can significantly improve production efficiency and reduce labor costs.

High precision: The application of CNC system ensures the accuracy of product size and shape.

Easy operation: The intelligent control system makes the equipment easy to operate and maintain.

Versatility: Can produce ceiling panels of different specifications and styles to meet different customer needs.

4. Application areas

Construction Sites: Suspended ceiling installations for temporary or permanent buildings.

Commercial space: such as offices, shopping malls and other ceiling projects that need to be quickly set up and dismantled.

Home decoration: Some high-end packaged container houses are used for family living, and the ceiling panels produced by ceiling panel equipment can be used in such decoration.

5. Advantages of use

Save time: Large-scale automated production reduces manual operation time.

Reduce costs: Automated equipment reduces labor costs and material waste.

Improved quality: Consistent production processes and quality control systems improve product quality.

6. Installation and maintenance

Installation: Professional technicians install and debug the equipment to ensure normal operation of the equipment.

Maintenance: Regularly inspect and maintain equipment, and promptly replace worn parts to ensure long-term stable operation of the equipment.

It can be seen from the above introduction that packaging container room ceiling panel equipment has significant advantages in improving production efficiency, reducing costs and ensuring product quality. Its wide application fields and powerful functions make it an indispensable and important equipment in the construction industry.

FEATURES AT A GLANCE

PRODUCT SPECIFICATIONS

MACHINE COMPONENTS

NO. Description Quantity (set)

1 5Thydraulic decoiler 1

2 Feeding platform1

3 Leveling part1

4 Online punching part 1

5 Forming system with ribs 1

6 Transmission system 1

7 Hydraulic guillotine 1

8 Support table 1

9 Hydraulic pump station 1

10 Control box 1

11 Spare parts and tools 1

PRODUCT CONFIGURATION

Feeding platform and leveling part:

Based on the right feeding platform, different feeding widths can be adjusted by adjusting the screws and nuts .

Forming rollers:

22 stations

roller material : Gcr15 # steel finishing and the surface is plated with hard chrome and polished

90mm solid shafts

shaft maerial : 45# steel processed

Electric control cabinet:

Vertical type

Delta brans or XIEJIE brand

or customzied brands

Hydraulic decoiler

1. Host volume: length 2.4 meters, width 1.55 meters, height 1.75 meters

2. Host weight: about 1.3 ton

3. Hydraulic pumping station: 5 solenoid valve pumping stations (the pump valve is Beijing Huade brand), power 3kw

380V

4. C-shaped steel: no power, passive feeding, hydraulic tensioning

5. Frame body: the base is made of 80*160*5 square tube, and the box body is welded with 12mm thick steel plate

6. Main shaft for supporting material: thick-walled seamless steel pipe is machined, and the shaft diameter is 133*25mm

7. Feeding width: 0-650mm

8. Inner diameter of steel coil: 470-700mm, ±20mm

9. The rated load capacity is within 5 tons

10. Hydraulic cylinder: expansion cylinder bore diameter 110mm, 1 piece (plus rotation)

11. Hydraulic pressing arm (Jinda)

advantage:

1. The load-bearing spindle is made of high-strength, fatigue-resistant rear wall seamless steel, which is processed by turning, with strong strength and heavy bearing.

2. The roll up adopts hydraulic control, which is convenient, fast and stable.

Automatic stacker

Automaticstacker

Speed customized

Product packaging

SALES AND SERVICE NETWORK

Successful Project

Projectin Argentina

Project in USA

Project in Mongolia

RECOMMENDED PRODUCTS

CE

CE

EXHIBITION AND CLIENTS

SAMPLE ROOM

FAQ

1. Package1). Container packing of the line suitable for overseas shipping

2). The subjects can be loaded by one 20ft FCL shipping.

3). Package style: Covered by plastic film, spare parts and some small parts packed in carton box.2. Delivery Time25-30 days (not include Chinese holiday) from order acceptance, deposit receipt and technical details agreement.3. Payment30% paid by T/T as deposit, 70% paid by T/T before loading.

4. Quality Warranty 15 months from time of loading by seller quality guarantee, life guarantee repair.

Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free. After the quality guarantee period, only charge the production cost of the spare parts.

Free technical supporting and maintenance consulting in lifetime.5. Assembly (Optional)

1). Machine will be tested completely in working before delivery to you.After receiving the machine and just need to connect the main power wires and can start to work. I will send you operation video , operation manual,too. very easy to operate.2). If you need engineer overseas serviceas, the installation charge can be discuss with Elena Whastapp 0086-13231741939 If you need engineer overseas services, the buyer has to pay the seller’s technician: Travel cost outside China (Including round flight charges), accommodation and foods (At least three-star hotel with air condition), solve the language problem, provide transportation from living place to the work place, and insurance out of China, etc.

WHY CHOOSE US?

Point 1: We are a big factory which has been developed 12 years. During the 12 years, we service each customers sincerity.

Point 2: Our company has great engineers who can design your profile perfectly. If you want to do a better machine, the first thing is to do a better design for profiles. We are a big and old factory so we have enough experience for designing the profiles.

Point 3: I am a very easy-going female salesperson, please tell me all your requirements for the machine, I can do my best to meet your needs. I can give you the best after-sale services. The machine is customized .So, about the machines' prices which have many .We can do your needed machine according to your request.

Point 4: About the machines' production, we have more than 50 machine making workers in our workshop and we have more than 20 sets of CNC machines to do processing rollers, shafts, base frames , cutters......About the machine making time, we guarantee you .

Point 5: About the machine acceptance , we can make videos and you see the machine running through videos . And also i will shoot the machine's opertaion video, connection video to you. Before machine loading, i will send you all necessary documemnts: operation video , wires connected videos, wiring diagram, floor diagram, oil circuit diagram, operation manual .....If necessary, we can send engineer to your there. No worries about the machine usage. We give you the best after-sale services.

Point 6: The warranty time is 15 months from the machine delivery from our factory. During the period, any problems about the machine, we replace the spare parts and helping you to solve problems freely. Exceed this period, we will also solve the problems freely for you , if need to replace some spare parts, only charge the spare parts and freight for you. Solving problems through videos is free for you. We give you the best after sale services.

Point 7:About the shipment, we have several long cooperated forwarder who can quote us the lowest sea freight . if you need us to ship for you, i can give u the best suitable sea freight . You don't need to worry about you can not deal with the shipment. Also , you can choose your own forwarder and I will cooperate with them throughout.