DETAILS

electric control cabinet

Product Overview

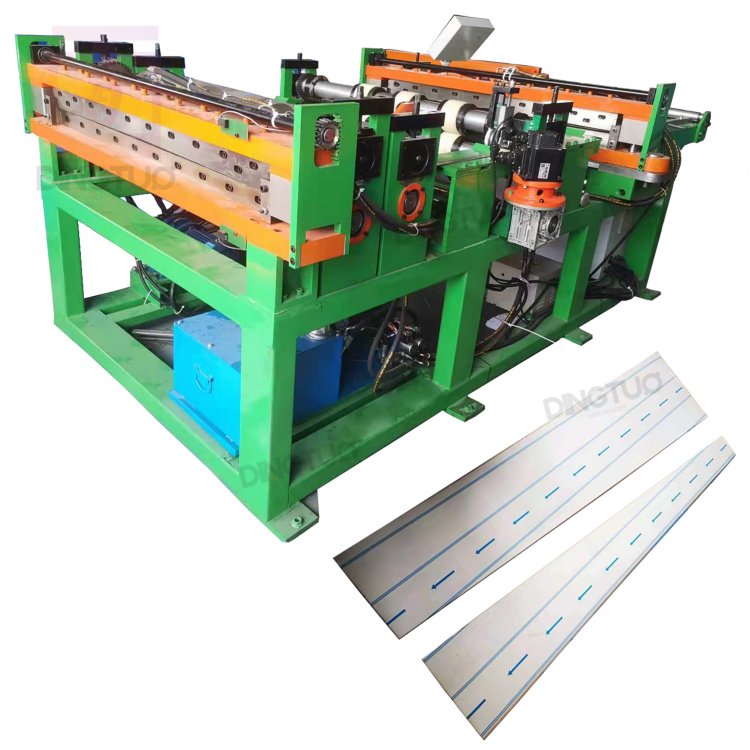

Oblique Slitting Machine

The oblique slitting forming machine is a slitting forming machine equipment used to obliquely cut out the required materials after positioning the color steel/aluminum magnesium manganese material roll.

This slitting machine needs to be customized. Used for straight and diagonal slitting of coil raw materials.Can be divided into rectangular, right-angled trapezoid, isosceles trapezoid and other shapes.

The equipment mainly includes double-head feeding rack, straight and inclined slitting host, and electric control cabinet.The whole machine is controlled by a computer system,hydraulic pre-cut system, and external chain transmission.Realize electrified control, convenient and quick operation, improve production efficiency, and reduce labor intensity.

Spherical roofs need to use oblique slitting machines to make roof and head panels.

The oblique slitting machine is complicated to make, and the requirements are relatively high. Mechanical, electrical and hydraulic pressure have coordination requirements, and the machine technical requirements are high.

The oblique slitting machine can be matched with the purchase of a straight tapered all-in-one bemo type standing seam forming machine. The raw material of the tapered panels is the panel made by the oblique slitting machine.

FEATURES AT A GLANCE

PRODUCT SPECIFICATIONS

MACHINE COMPONENTS

NO. Description Quantity (set)

1 decoiler 1

2 feeding platform 1

3 hydraulic pre-cutter 1

4 oblique slitting blade 1

5 guide shafts and rolelrs1

6 cut to length and straight slitting rollers 1

7 hydraulic post cut part1

8 Transmission system 1

9 Hydraulic pump station 1

10 Control box 1

11 Spare parts and tools 1

12 electric seamer 1

PRODUCT CONFIGURATION

Decoiler

1), type 5 tons without power manual tensioning passive unwinding type; 2) The positive and negative tooth rotation drives the

strut to tighten the connection mode; 3) Tension/reduction specification range 470mm--560mm

strut to tighten the connection mode; 3) Tension/reduction specification range 470mm--560mm

Feeding platform:

Feeding platform to guide the coil feeding

hydraulic pre cutting

Transverse cutting adopts hydraulic double-cylinder synchronous rack structure, power 2.2KW, can swing angle, used for oblique division of isosceles trapezoid

Oblique cutter

The oblique slitting has no power, matching the speed of the host, servo motor (1KW) drive, real-time positioning and adjusting

the position of the oblique slitting device, accurately controlling the oblique size; the maximum gradient is 150/1000

the position of the oblique slitting device, accurately controlling the oblique size; the maximum gradient is 150/1000

Hydraulic post cut for straight slitting cutting

The last one station is straight slitting, the roller diameter is 75mm, and 4 sets of knives are installed, which can be used for

trimming or straight slitting;

trimming or straight slitting;

Hydraulic pump station and motor :

2.2kw hydraulic pump station with cooling fan which can redece the oil temperature when machine working

electric control cabinetSchneider brand

SALES AND SERVICE NETWORK

Successful Project

Projectin USA

Project in RUSSIA

Project in ALGERIA

SIMILAR PRODUCTS

PACKING AND SHIPPING

EXHIBITION AND CLIENTS

SAMPLE ROOM

FAQ

1. Package1). Container packing of the line suitable for overseas shipping

2). The subjects can be loaded by LCL shipping.

3). Package style: Covered by plastic film, spare parts and some small parts packed in carton box.2. Delivery Time25-30 days (not include Chinese holiday) from order acceptance, deposit receipt and technical details agreement.3. Payment30% paid by T/T as deposit, 70% paid by T/T before loading.

4. Quality Warranty 15 months from time of loading by seller quality guarantee, life guarantee repair.

Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free. After the quality guarantee period, only charge the production cost of the spare parts.

Free technical supporting and maintenance consulting in lifetime.5. Assembly (Optional)

1). Machine will be tested completely in working before delivery to you.After receiving the machine and just need to connect the main power wires and can start to work. I will send you operation video , operation manual,too. very easy to operate.2). If you need engineer overseas serviceas, the installation charge can be discuss with Elena Whastapp 0086-13231741939 If you need engineer overseas services, the buyer has to pay the seller’s technician: Travel cost outside China (Including round flight charges), accommodation and foods (At least three-star hotel with air condition), solve the language problem, provide transportation from living place to the work place, and insurance out of China, etc.

WHY CHOOSE US?

Point 1: We are a big factory which has been developed 12 years. During the 12 years, we service each customers sincerity.

Point 2: Our company has great engineers who can design your profile perfectly. If you want to do a better machine, the first thing is to do a better design for profiles. We are a big and old factory so we have enough experience for designing the profiles.

Point 3: I am a very easy-going female salesperson, please tell me all your requirements for the machine, I can do my best to meet your needs. I can give you the best after-sale services. The machine is customized .So, about the machines' prices which have many .We can do your needed machine according to your request.

Point 4: About the machines' production, we have more than 50 machine making workers in our workshop and we have more than 20 sets of CNC machines to do processing rollers, shafts, base frames , cutters......About the machine making time, we guarantee you .

Point 5: About the machine acceptance , we can make videos and you see the machine running through videos . And also i will shoot the machine's opertaion video, connection video to you. Before machine loading, i will send you all necessary documemnts: operation video , wires connected videos, wiring diagram, floor diagram, oil circuit diagram, operation manual .....If necessary, we can send engineer to your there. No worries about the machine usage. We give you the best after-sale services.

Point 6: The warranty time is 15 months from the machine delivery from our factory. During the period, any problems about the machine, we replace the spare parts and helping you to solve problems freely. Exceed this period, we will also solve the problems freely for you , if need to replace some spare parts, only charge the spare parts and freight for you. Solving problems through videos is free for you. We give you the best after sale services.

Point 7:About the shipment, we have several long cooperated forwarder who can quote us the lowest sea freight . if you need us to ship for you, i can give u the best suitable sea freight . You don't need to worry about you can not deal with the shipment. Also , you can choose your own forwarder and I will cooperate with them throughout.