No | Item | Data | Note |

1 | raw material | Galvanized steel ,G350-G550 | it is better to use G550 material only |

2 | raw material thickness | 18/20/24 gauge (0.6-1.25mm) |

|

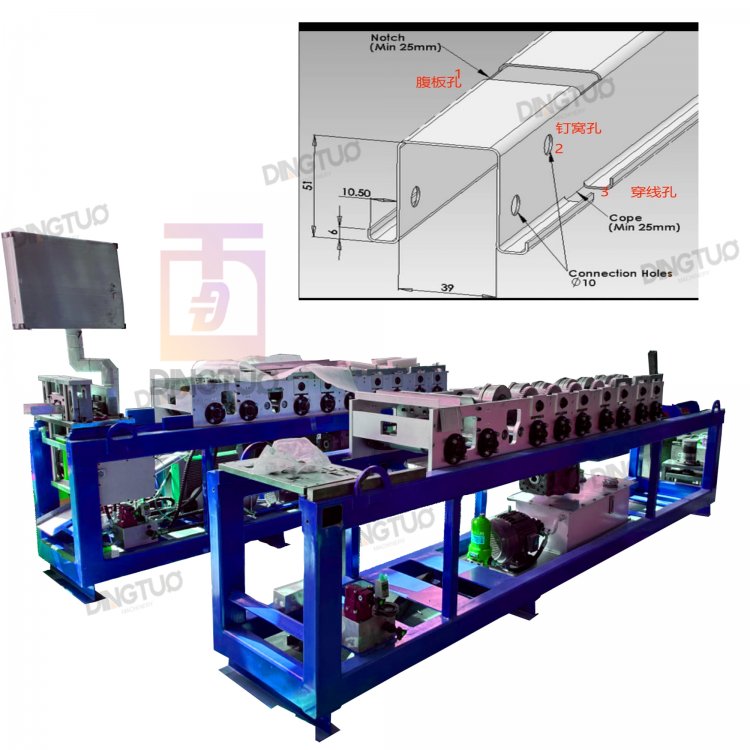

3 | sheet bottom width | 39 mm | can customzied the effective width,too. If you need , welcome to connect Ms.Elena 0086-13231741939 |

4 | sheeet height | 51mm | customzied the machine sheet sizes as your drawing . Any requests , welcome to connect Ms.Elena 0086-13231741939 |

6 | machine power | 2.2KW(2 in 1 decoiler and leveling machine motor power)+5.5KW (main servo motor power) +5.5KW (hydraulic pump station motor power) | 13.2 kw.h |

7 | Number of the punching groups | 5 sets of punching groups Model 1: web notch Model 2: Flange cut *2 dies Model 3: side hole Model 4: dimple hole Model 5: cut

| See the specific file i attached

(this is the standard perforation punching , if you need special perforation punching request, all can do, just provide your

detailed drawings)

any request, welcome to connect Ms.Elena 0086-13231741939 |

8 | machine transmission way | gears | any request, welcome to connect Ms.Elena 0086-13231741939 |

9 | Machine control screen type | Touch screen /mouse connection | Computer controlled automatically |

10 | Length counting method | OMRON (JAPAN ) brand encoder |

|

11 | Brand of main servo motor | INVT brand 7.5kw servo motor | This brand we used many years which quality has more suitable for our machine and can make machine running stable and not will be

impacted by other electric devices. And only this brand can match better with servo tracking none-stop motors |

12 | Voltage | 220V/380V / 415V / 480V ,50HZ/ 60HZ, 3 Phases or customized | voltage can be customzied as clients' request. Any requests , welcome to connect Ms.Elena 0086-13231741939 |

13 | roller material | Imported material, DC53. CNC center processing, HRC58-62°, fine grinding | Advantages of DC 53 material:High hardness, high strength, good wear resistance, good toughness/No cracks, long service life |

14 | shaft diameter | 40Cr material

quenching and tempering processing, fine grinding | Advantage of 40Cr material:After quenching and tempering, better cutting performance can be obtained, and comprehensive mechanical

properties such as higher strength and toughness can be obtained. The surface hardness after quenching can reach 45-52HRC. Alloy

structural steel such as 40Cr is suitable for shaft parts with high precision and high speed. After quenching and tempering, this

kind of steel has better comprehensive mechanical properties. |

15 | Material of cutter | Imported material

tungsten steel | Advantage of Tungsten steel (hard alloy) material : it has a series of excellent properties such as high hardness, wear

resistance, good strength and toughness, heat resistance and corrosion resistance, especially its high hardness and wear

resistance, even at a temperature of 500 ℃ Basically remain unchanged, still very high hardness at 1000 ℃. |

16 | Forming Speed | 30 m/min | Your thickness decided the machine speed with servo non-stop motors can reach max. 30m/min. The speed also decided by your

produced profiles’ length. More long profile length , more higher speed. |

17 | Machine input file | CSV/XML |

|

18 | Brand of inject printer | SOJET Dual print heads | waist height on both sides to print, the coding content can be set. See my attached video |

19 | Brand of PLC | Mitsubishi | JAPAN Brand |

20 | Brand of low voltage/switch/encoder/button | Schneider | France Brand |

21 | software | V T |

|

22 | Machine size | L3.3*W0.8*H1m |

|

23 | machine weight | 2000 KGS |

|

24 | Forming station | 9 stations | save materials when using machine |

25 | decoiler | 1-1.5 tons capacity 2 in 1 decoiler and leveling machine | manual tension and relex , active forward function |

26 | run out table | 1 piece | with send you the design drawing on computer |